| -

|

|

|

BIO GREEN

AMMONIA,

100% GREEN AND ORGANIC NITROGEN

This project, now a reality, is perhaps the most ambitious

we have developed. It is said that only 14% of the ammonia used as

fertilizer is consumed by humans through food. The rest ends up on

the ground or in the air.

Emissions in the absence of human

interference are 0.7 kg annually per hectare/year. Modern

agriculture has multiplied this figure by 25, causing the

modification of the natural nitrogen cycle with the consequences of

the contamination of soils, waters and the acidification of the

oceans.

Today we have the solution that replaces the Haber-Bosch

process, used successfully for more than 100 years, but which did

not consider environmental protection factors. |

|

|

|

BIOMIMETIC PRODUCTION OF NITROGEN FROM NATURAL ORIGIN

AND PLANTS.

Bio Green Ammonia is a reality, the project

is the most advanced technology that exists for the production of

nitrogen for agricultural use. Bio Green Ammonia, means

reducing to zero:

- All CO2 emissions generated

in the production of Nitrogen..

- All NH3 emissions generated in the production of

Nitrogen.

And more:

- Capture, store and reuse CO2 from the

atmosphere.

-

Produce nitrogen for agricultural use 100% ECO & ORGANIC. |

|

|

|

BIO GREEN AMMONIA MEANS PRODUCTION OF GREEN NITROGEN AND FERTILIZERS

WITH ZERO CARBON EMISSIONS |

|

BACKGROUND BACKGROUND

The nitrogen

used in agriculture basically comes in two forms: ammonia and urea

and derivatives of both.

AMMONIA

Ammonia is produced naturally through the

decomposition of organic matter, but the truth is that currently,

and for more than 80 years, the wrong large-scale industrial model

was created. The process used to obtain ammonia is the Haber-Bosch

process and its name comes from the first chemists who carried it

out: Fritz Haber and Carl Bosch.

UREA

The synthesis reaction for urea production involves

combining ammonia with CO2 under pressure to form

ammonium carbamate, which decomposes into urea and water. Unreacted

CO2 is recirculated. The main raw material to obtain this

compound is natural gas, which through a chemical process is first

converted into ammonia and then dehydrated to form, for example,

urea.

|

|

But what if we dispense with the synthesis industry

and natural gas and produce ORGANIC NITROGEN, 100% NATURAL, in a

sustainable and non-polluting model…

For this, there is currently only one model

and one possibility, Bio Green Ammonia, GREEN NITROGEN.

This private project, developed by KERVRAN LABS, is

developed in Malaga, Andalusia, SPAIN with a proprietary

technology (patent pending) called the UJADOS-GIL PROCESS,

which replaces and surpasses the Haber-Bosch process for the

following reasons, among many others:

- Energy consumption is minimal and is carried out with a

solar electric motor also developed for the project, which

does not require large photovoltaic infrastructures, just a

small installation of 20 square meters.

- Fossil fuels are not used, nor any other type of fuel, LPG,

hydrogen.

And the project is a reality that has already passed the

laboratory/prototype and pre-industrial phases, and is in

the beginning of production phase.

BIO GREEN AMMONIA IS A REALITY.

|

|

|

|

TWO

CONCATENATED METHODOLOGIES FOR ONE PRODUCT TWO

CONCATENATED METHODOLOGIES FOR ONE PRODUCT

Biomimicry and non-polluting models..

§

PROCESS 1

EXTRACTION THROUGH BASIC SOLUBILIZATION.

In the organic matrix of plant tissues that are used

as raw materials (fabaceae and legumes) where the nutrient to be

obtained is found: NITROGEN associated with other macro and

micronutrients in a complex form. It also naturally incorporates

percentages of iron, calcium and silicon. This association is

possible thanks to the fact that all these elements are found in an

organic matrix that allows their natural compatibility.

In production,

they are only used as pH modifiers or complements to natural

processes; short-chain carboxylic acids of plant and/or food origin

are used.

Under no circumstances are synthetic chemical

solvents USED, nor are EDTA, EDHA, ligno-sulfonic acid or any other

similar chelators used.

With this model, values of up to 5% or slightly

higher can be reached, depending on the nitrogen contained in the

fresh plant tissue and other factors such as temperature, extraction

speed, pH of the water, etc.

§

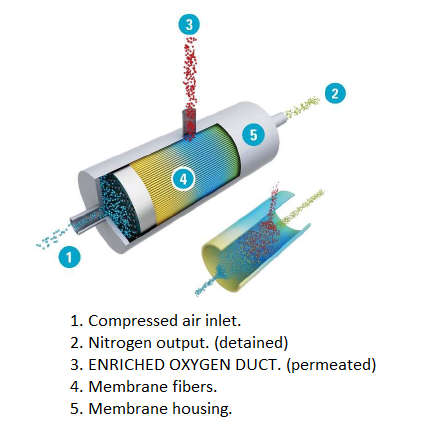

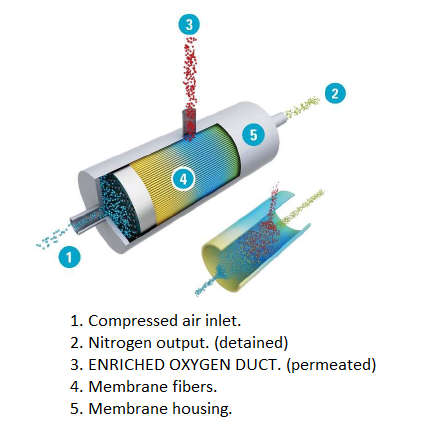

PROCESS 2

EXTRACTION BY CAPTURE OF ATMOSPHERIC CO2.

Nitrogen is captured from the air using a MECHANICAL

SYSTEM of polymeric membranes that allow the rapid passage of one

gas while minimizing the passage of other gases when a pressure

gradient is applied across the membrane. In this way, the membrane

separates oxygen and other “fast gases” from compressed air and thus

generates a nitrogen stream of 95% purity..

PRINCIPIOS DE FUNCIONAMIENTO

|

Air from the atmosphere is introduced through the air

filter, passes through the air inlet valve and enters the

compression element.

This compressed air is forced through the air

separator, past the minimum pressure valve and into the reservoir (on

TM units).

The purities of nitrogen obtained from air by mechanical separation

range from 95% to 99.5% (residual oxygen content from 5% to 0.1%).

The generator consists of one or several high-performance membranes.

This membrane configuration ensures maximum output of

compressed nitrogen for minimum input of compressed air, over a wide

range of operating conditions.

To allow continuous operation these nitrogen generators are equipped

with a top quality 2-stage pre-filtration system that guarantees an

inlet air quality according to ISO8573-1:2010.

This eliminates the risk of membrane damage from poor quality

compressed air supply, poor starts and unexpected stops. |

|

|

|

The plant tissue that was used in PHASE 1 and from

which the maximum possible nitrogen has been obtained, remains as an

amalgam of decomposing organic matter that is stored as a base to

create a natural ecosystem similar to that of a peat bog.

Peat forms as a result of the partial rotting and carbonization of

vegetation in the acidic water of swamps, marshes, and wetlands. The

formation of a peat bog is relatively slow as a consequence of low

microbial activity, due to the acidity of the water or the low

concentration of oxygen.

The passing of the years produces an accumulation of

peat that can reach several meters thick, at a growth rate that is

estimated to be between half and ten centimeters every hundred years.

But... what if we vary the conditions with a BIOMIMETICAL

model applying the following vectors?:

Promoting that water, instead of an acidic environment, is in an

alkaline environment. With plant species that do it naturally.l.

-

Enhancing the microbial

activity of water in a state of putrefaction, the “peatlands” in

production ponds used for production, with organisms that belong

to the subgroup of proteobacteria, which includes the following

genera: Allorhizobium, Azorhizobium, Bradyrhizobium,

Mesorhizobium, Rhizobium and Sinorhizobium, Ensifer and others

with similar biological behavior.

-

Conducting captured

atmospheric nitrogen to this particular ecosystem to enhance the

activity of microorganisms and their fixation in water.

It happens that we are in an environment similar to that of a peat

bog, but with a greater potential for nitrogen fixation in the water

and a much higher rate, and can even reach values of 50% of nitrogen

solubilized in water.

And what

happens to the C02 that is produced in the biological

production processes of Bio Green Ammonia?

It is also captured and

consumed by nitrogen-fixing microorganisms and by plant organisms

that develop on the surface of the “production peatlands.” Another

fraction is taken to pools for the production of calcium carbonate

in a biomimetic and natural way.

Biological

Nitrogen Fixation (BNF)

As is known, nitrogen

fixation by bacteria occurs when they convert gaseous nitrogen from

the air and CO2 into inorganic compounds. Although the

role of legumes is undeniable, the task is too difficult for them

alone. In fact, it is normal for symbiotic nitrogen fixation to

occur between legumes and bacteria. It is common for Rhizobium and

others to colonize the roots.

However, it is not the only

symbiotic nitrogen fixation in legumes: biological nitrogen fixation

also occurs with other associated and free organisms, which are

those found in the substrate of the peat bogs used in our

Bio Green Ammonia production

process. which is successively decanted to the bottom of the water

under the substrate until the desired percentage is reached..

|

|

|

|

-

IT IS A SUSTAINABLE MODEL WHOSE ONLY

RESIDUAL EMISSION IS OXYGEN FROM THE SEPARATION OF

ATMOSPHERIC NITROGEN.

-

NO CHEMICAL SOLVENTS ARE USED.

-

IT'S AN ENERGY SELF-SUFFICIENT MODEL,

EQUIPPED WITH AN ENERGY PRODUCTION UNIT WITH AN

ELECTRICITY GENERATOR WHICH IS USED FOR PUMPING AND

OPERATION OF THE NITROGEN CAPTURER.

-

DOES NOT REQUIRE SOLAR PANELS, COMPLEX

INSTALLATIONS.

-

DOES NOT CONSUME FOSSIL FUELS.

-

IT DOES NOT PRODUCE WASTE, NEITHER SOLID

OR LIQUID.

-

CAPTURES, STORES AND REUSES

ATMOSPHERIC CO2, GENERATING OTHER SUSTAINABLE PRODUCT

AND INDUSTRIAL MODELS..

|

|

|

|

Agricultural Inputs (final products) that incorporate

CERTIFIED ORGANIC NITROGEN produced by Bio Green Ammonia. |

|

|

|

|

|

Join the Natural and 100% Sustainable Agriculture model

of ORGANIC NITROGEN produced by Bio Green Ammonia..

|

-

Farmer or

agricultural producer who wants to use the organic and

sustainable products of Bio Green Ammonia to

create a NATURAL AGRICULTURE model.

-

Fertilizer

Manufacturerthat want to use green and organic nitrogen

as an ingredient in your products or formulations..

-

Marketer or

Distributor that want to distribute

Green and Organic

Nitrogen..

-

Financial

investor who wants to participate in a key future

project for the environment and agriculture..

Contact

now:

bga@biogreenammonia.com Contact

now:

bga@biogreenammonia.com |

| |

|

|

|

|

|

Copyright 2023 © KERVRAN LABS

Tecnología y Consultoría Medioambiental

28806 Málaga. Spain |

|

The Environmental Technologies Experts. |